Main Parts of Lubrication System:

➤ Oil Pump:

Driven by the camshaft, the camshaft, the pump force the oil from the sump to the main oil gallery. Four types of oil pumps are used:

Gear type Oil pump

➮ Gear type oil pump: This type of pump is most commonly used. It consists of two gears fitted in a casing. The casing has two ports

➮ Rotor type oil pump: It consists of two rotors⟶ inner rotor and outer rotor. The inner rotor has four lobes whereas the outer rotor has five lobes. When the rotors rotate, oil is forced towards the main oil gallery.

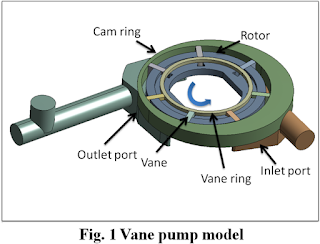

➮ Vane type oil pump: This type of oil pump is not much in use. It consists of a cylindrical body with inlet and outlet passages. It has a drum inside which vane rotates eccentrically. When the drum is rotated by the engine, oil is sucked from the inlet passage and moved through the outlet passage.

➮ Plunger type of oil pump: This type of pump is seldom used now. It consists of a plunger. When moves up and down in the body. When it moves up, Oil is sucked through the inlet passage and when it moves down, the oil is forced through the outlet passage into the main oil gallery.

➤Main oil Gallery:

This runs the length of the engine. Holes drilled from the gallery allow oil to flow to the bearing surfaces.

➤Relief valve:

Relief Valve

It is spring-loaded and opens when the pressure exceeds the maximum allowed Limit. It is generally fitted in the gallery.

Two types of relief valve are in use:

(i) Ball type

(ii) Plunger type

➤ Filters:

In addition to the gauze screen that prevents pieces of metal entering the pump there is an external filter, which can be replaced from time to time, There are two types of oil filter systems:

➮ In by-pass system, the whole of the oil does not pass through the filter. Some of the oil without being filtered goes to the bearings.

Remaining oil passes through the filter.

➮ In full-flow system, the whole oil passes first through the filter and then goes to the bearings.͒➤

The oil filters used are of three types:

Cartridge type

➮ Cartridge type: It consists of a filtering element placed in a metallic casing. The impure lubricating oil from the oil pump enters the casing through the filtering element, which takes up all the impurities.

Edge type oil filter

➮ Edge type oil filter: It consists of a number of discs in a casing through which the oil passes. The alternate discs are mounted over a central spindle and the discs between these are fixed to separate square rod. There is very small clearance between the two. When the oil flows through this small clearance, it leaves impurities on the disc peripheries.

Centrifugal type oil Filter

➮ Centrifugal type oil filter: It consists of stationary casing, rotor casing, central spindle and tubes with jets. The impure oil enters the hollow central spindle and through the rotor casing. From the rotor casing the oil goes in the tubes, at the ends of which jets are attached. The oil passes through these jets under pressure, the reaction of which gives the motion to the rotor casing so that it starts rotating. The oil from jets impinges on the walls of the stationary casing under heavy pressure, Where the impurities are retained and clean oil falls below, which is takes for use.

No comments:

Post a Comment